When it comes to lifting and rigging tasks, the choice of equipment can significantly impact safety and efficiency. Webbing slings are a popular and versatile option for many industries, offering a range of benefits when used correctly. This guide will help you understand webbing slings one way sling, their types, benefits, and best practices for safe use.

What Are Webbing Slings?

Webbing slings are lifting devices made from woven fabric, typically polyester or nylon, designed to lift and support heavy loads. They are a crucial component in the rigging and lifting industry, providing a flexible, strong, and reliable means to handle various materials and equipment.

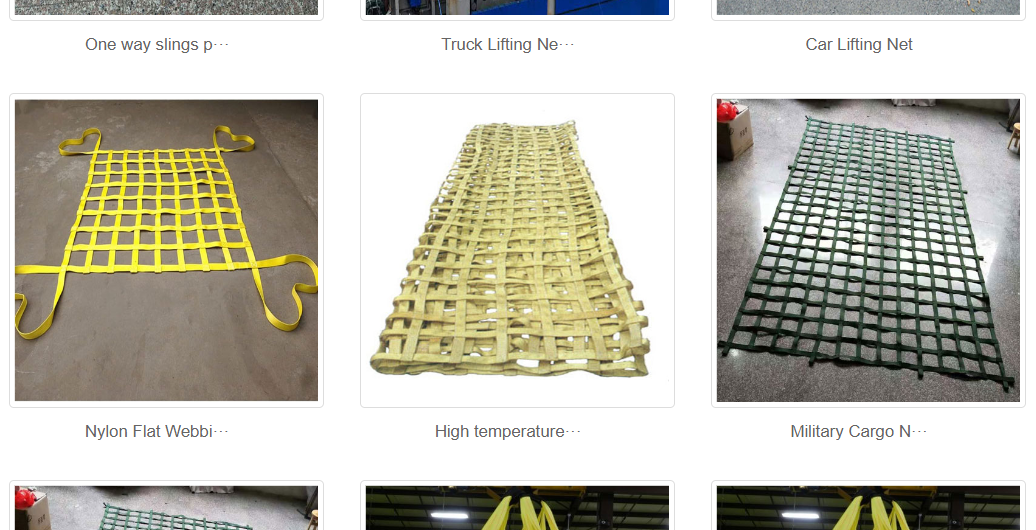

Types of Webbing Slings

- Flat Webbing Slings

These are the most common type of webbing sling. Flat webbing slings are versatile and can be used in a variety of lifting situations. They are ideal for loads with flat surfaces and are available in different widths and lengths. - Round Slings

Round slings, also known as endless slings, are made from a circular piece of webbing. They are designed to handle loads with uneven surfaces and are known for their flexibility and ability to conform to the shape of the load. - Sleeve Slings

Sleeve slings are webbing slings that come with a protective sleeve over the webbing. This sleeve helps prevent wear and tear on the sling, extending its lifespan and enhancing safety.

Benefits of Using Webbing Slings

- Flexibility and Strength

Webbing slings offer excellent flexibility, allowing them to handle loads of varying shapes and sizes. Despite their flexibility, they are strong and durable, capable of lifting heavy loads with ease. - Lightweight and Easy to Handle

Unlike chains and ropes, webbing slings are lightweight, making them easier to handle and manipulate. This ease of use contributes to faster and more efficient lifting operations. - Reduced Risk of Damage

The soft fabric of webbing slings minimizes the risk of damage to the load being lifted. This is particularly beneficial for lifting delicate or finished products that could be scratched or otherwise damaged by more rigid lifting equipment. - Cost-Effective

Webbing slings are generally more affordable compared to other lifting options such as chains or steel ropes. This cost-effectiveness, combined with their durability, makes them a popular choice for many lifting applications.

Choosing the Right Webbing Sling

- Determine the Load Requirements

Assess the weight and dimensions of the load you need to lift. This will help you choose the appropriate type and size of webbing sling. - Consider the Environment

The working environment can impact the choice of webbing sling. For example, if the sling will be exposed to chemicals or extreme temperatures, choose a sling with suitable resistance. - Check for Compliance

Ensure that the webbing sling meets industry standards and regulations. This is crucial for safety and ensuring that the sling will perform as expected. - Inspect Regularly

Regular inspection of webbing slings is essential to ensure they are in good condition. Look for signs of wear and tear, such as fraying or cuts, and replace any damaged slings immediately.

Best Practices for Safe Use

- Follow Manufacturer Guidelines

Always adhere to the manufacturer’s guidelines for the proper use of webbing slings. This includes load limits, handling instructions, and maintenance requirements. - Use Proper Rigging Techniques

Ensure that webbing slings are used correctly with appropriate rigging techniques. This includes proper hitching methods and avoiding sharp edges that could damage the sling. - Avoid Overloading

Never exceed the rated capacity of the webbing sling. Overloading can lead to sling failure and pose significant safety risks. - Store Properly

Store webbing slings in a clean, dry place to prevent damage. Avoid exposing them to direct sunlight or harsh chemicals.

Conclusion

Webbing slings are an essential tool for safe and efficient lifting and rigging. By understanding the different types of webbing slings, their benefits, and best practices for use, you can ensure that your lifting operations are both safe and effective. For high-quality webbing slings and round slings that meet industry standards, visit Lift Sling Net Belt Factory for all your lifting and rigging needs.